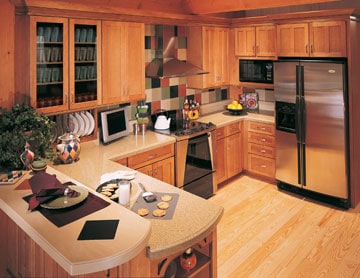

Expert advice on how to buy new kitchen cabinets, including help with types and sizes, materials, judging quality, and where to buy kitchen cabinets.

Is your family one of the estimated 5 million that will be living on pizza and frozen dinners during a kitchen remodel this year? If so, you can speed up the process, make informed decisions, and focus your resources wisely by doing your homework early.

Start with your kitchen cabinets—not only will they be your kitchen’s most dominant element, but they’ll also probably take longer to get than any other component.

As you begin to shop for kitchen cabinets, you’ll discover a nearly overwhelming variety: laminates, hardwoods, veneers, lacquered finishes, and much more in hundreds of different styles, configurations, and sizes.

You’ll find ready-to-assemble cabinets that can outfit a kitchen for under $1,000 and high-end cabinets that cost more than some houses. How do you choose the right ones for your kitchen? The answer is to know what you’re looking for before you set out, and then when you shop, ask lots of questions and study floor models.

You’ll find ready-to-assemble cabinets that can outfit a kitchen for under $1,000 and high-end cabinets that cost more than some houses. How do you choose the right ones for your kitchen? The answer is to know what you’re looking for before you set out, and then when you shop, ask lots of questions and study floor models.

In addition to many sizes, styles, and finishes, it’s not unusual to discover that a single company offers more than one cabinet line, each distinguished by different pricing and quality—and up to a dozen different door types.

Styles typically range from contemporary laminates to traditional hardwoods such as oak and cherry. Most companies also offer several finishes for natural wood cabinetry.

One way dealers can offer a broad selection without carrying an unwieldy inventory is to utilize a “box and door” program. They carry standard-sized cabinet “boxes” and a wide range of door and drawer fronts to fit the boxes.

Face Frame vs. Frameless

When shopping for cabinets, you’ll find two main types: face frame and frameless (or “European-style”). Though some manufacturers make both, most make only one or the other. Despite a trend toward frameless cabinets, about two-thirds of the cabinets made by American manufacturers are the face-frame type.

Face-frame Cabinet

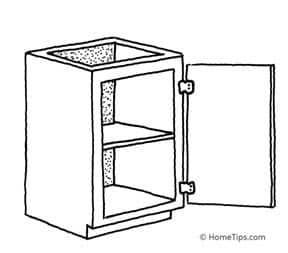

With a face-frame cabinet, as the name implies, the 1/2- or 3/4-inch plywood or particleboard front edges of the cabinet box are masked with a frame made from 3/4 by 1 1/2-inch hardwood.

The frame adds rigidity to the cabinet and provides a strong base for attaching hinges. Doors or draw fronts normally overlay the frame, but they may be flush or offset. Standard offset hinges are partially visible from the front.

Because the face frame adds rigidity, face-frame cabinets don’t have a top panel or a full back (or the back may be made of quite thin material). Wall cabinets are designed to be hung from a rail on the wall. Base cabinets have integral bases. When butted against an irregular wall, the frame around the perimeter can be shaved to fit.

A drawback of face-frame cabinets is that the frame narrows the opening size utilized by cabinet doors and drawers.

Frameless Cabinet

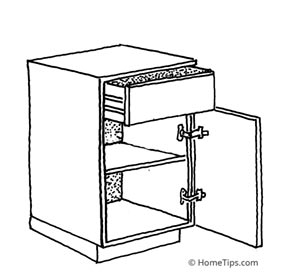

Frameless European-style cabinets are made up of panels finished on both sides and edged with a simple laminate banding or narrow strip. Most types utilize the “32mm system.” With these, holes are drilled on 32mm increments vertically along each cabinet side panel.

European hinges, cabinet joinery fittings, drawer slides, shelf pins, and other hardware fasten to these holes, providing plenty of versatility and adaptability.

With flush doors and hidden hinges, frameless cabinets have a contemporary construction that is suitable to being covered with wood veneer or plastic laminate. The front edges of each plywood or particleboard box are also covered with a thin banding that matches the panel surface. Frameless cabinets usually have a panel top and back, and base units are commonly mounted on top of a separate plinth or toekick.

Most ready-to-assemble cabinets are frameless. Assembling and modifying frameless cabinets is relatively easy.

Stock vs. Custom Cabinets

Unlike custom cabinets, which are made to the specifications of a particular order, stock cabinets are manufactured in standard sizes. The manufacturer holds them in inventory or ships them to regional distributors or dealers who sell them at retail.

Just as a handcrafted chair costs more than a mass-produced one, custom cabinets cost more than stock. Whether you have custom cabinets made in a local cabinet shop or by a large custom manufacturer, you pay for the time and talents of experienced cabinetmakers.

Custom cabinets require a lot of personal attention and time because they’re designed and built from scratch. A 6-to-12-week waiting period is typical. Of course, for high-end kitchens or those requiring special cabinet sizes, configurations, or finishes, the premium is usually well worth it.

Price and delivery time are the strongest advantages of stock cabinets. These cabinets benefit from the economies of mass production, so they tend to cost from one-third to two-thirds less than similar-looking custom cabinets. Instead of paying $300 to $1,200 per lineal foot for custom cabinets, you’re looking at between $75 and $250 per lineal foot for stock.

Delivery time varies, depending on availability and the company’s distribution methods, but it rarely exceeds two or three weeks. Cabinets warehoused locally may be available the same day, and ready-to-assemble (RTA) knock-down cabinets sold over the counter are often cash-and-carry.

There is sometimes a fine line between custom and stock cabinetry. Many large custom manufacturers simplify ordering and manufacturing by offering a wide range of standard sizes and finishes with literally thousands of options.

They can modify these by altering size, customizing finishes or colors, adding accessories, or changing configurations. Even small cabinet-making shops often buy pre-manufactured parts-doors and drawer fronts that they integrate into custom cabinets.

High-End Cabinets

If you fallen in love with some of the European cabinets you’ve seen on Houzz or in home decorating magazines, get your checkbook ready.

Allmilmo, SieMatic, Poggenpohl, and a few other European manufacturers offer cabinets that are truly beautiful and are clearly meant for high-end kitchens.

Most average about $30,000 per kitchen, and some far exceed that. Also be prepared to wait from 6 to 16 weeks, depending on the company and your order.

Because highly individualized kitchens may be created from imported cabinets, they’re referred to as “custom.” Actually, some cabinet widths can be modified and you can order some special cabinets, but, for the most part, you order within a wide range of standard sizes and finishes.

The German company Allmilmo, for example, offers about 120 different looks, with surfaces that include laminates, wood veneers, lacquer finishes, and hardwoods such as maple, spruce, mahogany, and beech. All have frameless, melamine-laminated carcasses. The drawers are high-grade “Meta-Box” drawer systems with metal sides, integrated full-extension slides, and melamine bottoms.

SieMatic, with lines made in Germany and Canada and with some doors made domestically, also markets a wide range of standard sizes in styles from country hardwood cabinets to high-gloss, lacquered contemporary models.

In addition, SieMatic distributes Smallbone Handmade English Cabinetry, a line of beautifully made wood cabinets, including the very popular “unfitted” cabinets. Unlike typical cabinets, which are installed in runs, these are made more like individual furniture pieces. Installed and handpainted on site by specially trained craftspersons, these cabinets push the upper limits of price, averaging from $45,000 to $60,000 and topping out well over $100,000.

With Poggenpohl cabinetry, a German line, you work with predetermined sizes and fronts to create a system with a highly custom look. Of the European-style contemporary products on the market, Poggenpohl cabinets are considered some of the highest quality and are also among the highest priced.

Judging Cabinet Quality

Though production cabinets may not rival the quality of handmade cabinets, they do offer consistency. Many stock cabinets are manufactured with demanding tolerances to ensure quality. In fact, because of the sophisticated equipment used in today’s cabinet manufacturing, the quality of machining may be superior to what most small cabinet shops can offer.

One of the advantages of buying stock cabinets is that you can inspect them before you buy. If you shop around, you’ll discover that some are more “shlock” than stock.

Heavily discounted cabinets offered through lumberyards are highly suspect. Beware of photo-simulated wood grain, paper-thin laminates, low-quality or mismatched woods, and haphazard joinery.

The first place to look when checking quality is a drawer. Study how it’s made-the detailing of the joinery, the quality of the inner surfaces, the fit of the pieces, and how well it glides in its tracks. Is it on high-quality ball-bearing extensions, moderate-quality rollers, or cheap plastic runners? Check to see how far the drawer extends out.

Then check a cabinet door for proper fit and ease of action. Check any edge banding around the perimeter for workmanship. Note whether the hinges are adjustable and how far the door will swing open.

When buying stock cabinets, you usually pay upfront, which is why a thorough inspection is critical. Once you get them home and installed, you’ll have little recourse if you then discover that there are flaws in the design or workmanship.

Cabinet Sizes & Options

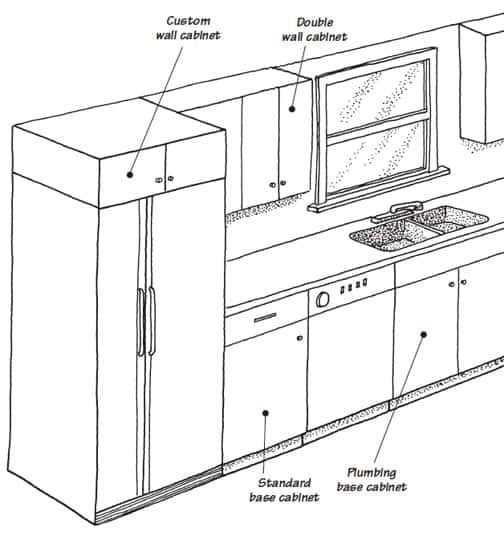

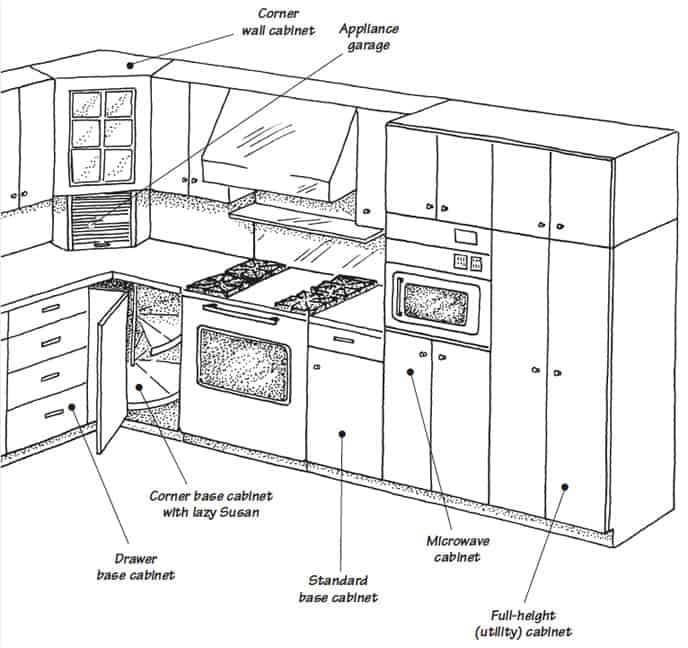

Most large manufacturers offer stock base and wall cabinets in widths ranging from 9 inches to 48 inches in 3-inch increments. Upper cabinet heights run 12, 18, and 24 inches for over sinks and stoves and 30, 36, and 42 inches for above counters.

Matching tall cabinets are made in 84-, 90-, and 96-inch heights. These heights are planned for standard 8-foot ceilings. Trim panels are sold for covering gaps between the cabinets and walls or ceilings. These are usually marked and cut to precisely fit adjoining surfaces.

If your kitchen design calls for a fairly unusual installation, you may still be able to accommodate it with stock cabinets, using a little creativity. For example, you might order additional materials from the manufacturer such as prefinished plywood sheets and hardwood pieces that match the cabinets. You can then have these sheets fabricated to create fillers, soffits, angled connections, islands, and so forth.

Kitchen Cabinet Modifications

Many cabinet manufacturers offer standard modifications to their cabinets at an additional cost. For example, they will reduce or increase cabinet depths; install breadboards, wine racks, or roll-out shelves; modify toe kicks or door attachments; and upgrade cabinets with oak-lined interiors or leaded-glass doors.

You may also be able to special order such accessories as knife racks, spice racks, wine racks, lazy Susans, and specialty pull-outs such as ironing boards. Some manufacturers will even build one-of-a-kind cabinets for an extra charge that ranges from about 25% to 50% above the cost of a similar cabinet in the line.

Even if a stock manufacturer does not have the capability of offering specialty accessories, you can order them through a cabinetmaker and have them installed independently. Most are designed to fit standard stock cabinet sizes.

Non-Toxic, Formaldehyde-Free Kitchen Cabinets

You might not think of your kitchen cabinets as having an effect on your home’s air quality. However, some materials and finishes used in their manufacture may contain formaldehyde. If inhaled, this can cause a condition that increases your sensitivity to other chemicals, such as those in paints, finishes, and even cosmetics. Even small amounts of formaldehyde can increase your risk of nose- and lung-related cancers.

Stock cabinets are often made from medium-density fiberboard (MDF), which is essentially the waste from lumber mills (sawdust and shavings) pressed together with resin to create a solid piece of material. That resin, and some of the finishes used to stain and seal the members, may contain formaldehyde.

To avoid the health risks and environmental effects of formaldehyde, you can install cabinetry made of solid wood or a non-toxic material such as Masonite’s PrimeBoard.

Unlike MDF, PrimeBoard is made from wheat straw and a non-formaldehyde resin. If you choose solid wood, try to choose an environmentally sustainable material for the entire cabinet.

Non-toxic “green” cabinetry can be hard to find and is expensive because only a few manufacturers produce it-although more are beginning to offer formaldehyde-free products. To keep your budget in check, try looking for used solid-wood cabinets at salvage-supply stores, and install metal shelving where its appearance won’t be prominent, such as in the pantry.

Cabinet Hardware

Hinges, cabinet knobs and pulls, and hardware for organization: The right hardware can make cabinets excel at beauty, efficiency, and ease of operation.

Reaching well beyond their function of providing storage, cabinets outfitted with special pullout racks, drawers, and accessory holders can claim every inch of storage space, putting the cabinets’ contents within easy reach. And, of course, visible cabinet hardware can set the style for an entire room.

Where to Buy Cabinets

Cabinets are sold primarily through kitchen cabinet dealers and showrooms, home improvement centers, lumberyards, and some kitchen appliance stores. Some companies sell cabinetry only through a controlled network of studios or retail outlets.

You can locate stock cabinet dealers by contacting manufacturers (see Resources in Your Area) and asking for referrals. Or consult your telephone directory or the National Kitchen & Bath Association (800-THE-NKBA or www.nkba.org) for help in locating kitchen cabinet showrooms and other outlets near you.

If you happen to have an Ikea retail outlet in your area, be sure to check its offerings. This discount chain sells a wide range of knock-down European-style stock cabinets with several door styles at very affordable prices. There you can make an appointment with a store design person who will help you configure your kitchen and put together your order.

You can choose from a dozen or more door styles and several different pulls and accessories. Goods are sold on a cash-and-carry basis, knocked down in flat boxes. You can assemble and mount them yourself to save money or you can arrange for delivery and installation by a contractor.

With any system, it’s often a good idea to get design help in specifying your needs. Unless you know exactly what you need, it pays to purchase through cabinet dealers who can offer some assistance.

In addition to normal services, some dealers offer a computerized design service; they’ll plot your kitchen on a computer and print out drawings and a materials list. These are great for helping you visualize your finished kitchen.

Unless you’re adept at carpentry projects, installing cabinetry is a job for a professional with the right skills and tools, especially for base cabinets, which will also need a countertop installed. If you are an experienced do-it-yourselfer, see How to Install Kitchen Cabinets.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: