An expert guide on the best posts and beams for your patio roof projects, this article covers post, column, and beam types, as well as the best materials for patio posts.

The main structural members of patio and deck overheads are posts or columns and beams, which run from post to post or from post to ledger. The beams support the roof rafters or joists, which in turn hold the roofing material.

Minimum sizes of posts and beams are set by engineering requirements and are strictly governed by local building codes.

Before beginning construction, consider finishing all of the lumber you will be using. In most cases, it’s much easier to apply a finish to the lumber when it’s sitting on sawhorses than when you’re standing on top of a ladder. If you prefinish the wood, plan to touch it up after construction is complete.

Patio Roof Posts & Columns

Posts and columns may be made from several types of materials. Here we look at the most common: solid lumber such as 4 by 4s, 6 by 6s, and 8 by 8s. Sometimes they’e built up from more than one size of lumber.

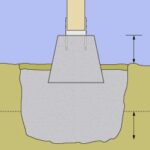

Any post that will touch the ground should be pressure-treated for decay resistance. Posts offer plenty of latitude for detailing—you can rout them, cut them, build up interesting profiles, or nail on decorative pieces to add visual interest.

Patio Roof Beams

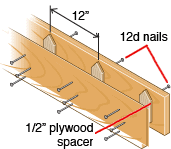

Beams can be solid lumber or be built from lengths of 2-by lumber nailed together with 1/2-inch pressure-treated plywood spacers in between (this forms a 3 1/2-inch-thick beam that is equal to the width of a 4-by post).

A built-up beam is easiest to handle because you can assemble it near its final destination, but making one involves a little more labor. In highly visible areas, a single, solid beam generally looks better.

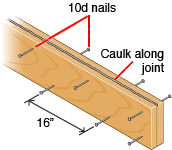

You can also build up a 3-inch-wide beam without spacers. Just nail together the two boards by driving 10d galvanized nails along both sides every 16 inches, staggering them as shown above.Apply a bead of silicone caulk to the joint between the boards to prevent moisture from seeping between them. Be sure the crowns (the “high” side of a curve or warp along the edge of a board) on the pieces align; then, when you mount the beam on the posts, place the crown side up.

If you must assemble a long, built-up beam from shorter lengths, stagger the joints between successive layers and plan for each of these joints to fall directly over a post.

Some designs use paired 2-by joists to substitute for beams. Generally speaking, these partnered beams have a less weighty, airier appearance and are easier to handle than a single beam.

Patio Roof Post & Column Options

In addition to the ever-popular wood, posts for outdoor structures can be made from other materials, including concrete and steel. Most often, alternative materials are chosen because the structure needs additional strength or for style reasons—to better complement the home’s architectural style or landscape.

Architectural Posts & Columns

Many millworks produce classical and decorative columns, available through dealers. Those that need to function as structural members are usually made from solid wood, aluminum, or fiberglass composites.

Columns that do not need to support the structure usually have a post made of wood or steel covered by a decorative “shell” that may be made from wood, aluminum, fiberglass composites, or polyurethane. You can also purchase columns in kit form and customize them with caps and bases to create the decorative look you want.

Concrete & Stucco Columns

Columns made from concrete are produced using wood forms (for square or rectangular) or fiber tubes (for round) into which concrete is poured. Columns intended to be stuccoed may be built from concrete blocks or have a frame made from wood with a plywood sheathing.

Steel Columns

Due to their expense, steel columns are rarely made for residential applications unless the structure is large and the ground or siting is unstable, requiring that they be custom-fabricated. However, because steel doesn’t burn, rot, or get eaten by termites, it does provide considerable value. Steel columns are often covered with a decorative wood facade.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: