Tired of noisy neighbors or street traffic? Discover DIY soundproofing tips to reduce noise in your home. Learn how to add mass, decouple drywall, and seal gaps to block unwanted sounds.

Walls are your first line of defense against unwanted noise, whether it’s from bustling streets, noisy neighbors, or other rooms in your home. If you’re tired of being disturbed by sounds seeping through your walls, it’s time to explore the world of soundproofing.

Understanding Sound Transmission Through Walls

Before we dive into the solutions, let’s understand how sound travels through walls. There are two main ways:

- Airborne noise: This is sound that travels through the air, such as voices, music, or traffic noise. It can pass through gaps, cracks, or even directly through the wall material.

- Structure-borne noise: This is sound that travels through the building’s structure, like footsteps or vibrations from appliances. It’s transmitted through the wall studs, floor joists, and other structural elements.

Effective soundproofing tackles both types of noise by using a combination of sound-blocking and sound-absorbing materials and techniques.

Key Soundproofing Principles and Techniques

The core principles behind effective soundproofing involve:

- Mass: Adding makes it harder for sound waves to vibrate the wall and pass through.

- Damping: Damping materials convert sound energy into heat, reducing its ability to travel.

- Decoupling: Separating the two sides of a wall prevents sound vibrations from passing directly from one side to the other.

- Absorption: Sound-absorbing materials reduce echoes and reverberation within a room, improving sound quality and minimizing noise transmission.

Let’s explore how these principles apply to both existing walls and new construction.

Soundproofing Existing Walls

Even without major renovations, you can significantly improve the soundproofing of your existing walls:

- Add Mass

- Consider adding another layer of ⅝-inch drywall to the existing wall for better sound blocking.

- Apply Green Glue damping compound between the layers for added sound reduction.

- Install Mass Loaded Vinyl (MLV), a dense, flexible material that can be added directly to the wall or sandwiched between drywall layers for superior sound blocking.

- Decouple

- If you have access to the wall studs, install resilient channels before adding a new layer of drywall. This decouples the drywall from the studs, reducing vibration and sound transmission.

- Seal & Absorb

- Inspect the wall for any gaps or cracks around outlets, switches, or baseboards and seal them with acoustic caulk or sealant.

- Add acoustic panels to the room. While they primarily absorb sound within a room, they can also contribute to overall noise reduction.

By understanding the principles of soundproofing and employing these techniques, you can create a quieter and more peaceful living space. Remember, soundproofing is most effective when you address all potential sound leaks, including windows, doors, and electrical outlets. If you’re undertaking a major renovation or building a new home, consider incorporating soundproofing into the wall construction itself for optimal results from the start.

Soundproofing New Walls: Build It Quiet from the Start

When building new walls or undertaking major renovations, you have a golden opportunity to integrate soundproofing directly into the construction process. This allows you to achieve superior noise reduction compared to retrofitting existing walls.

Key Techniques for New Wall Construction

Staggered stud walls. Instead of building a traditional wall with a single row of studs, construct a staggered stud wall with two separate rows of studs offset from each other. This creates a wider wall cavity and reduces the transfer of vibrations between the two sides.

Double wall construction. Build two separate walls with a small air gap between them. This air gap acts as an additional sound barrier.

Resilient channels. Incorporate resilient channels on one or both sides of the wall before attaching drywall. These metal channels flex slightly, decoupling the drywall from the studs and minimizing sound transmission.

This video shows how to install drywall on the CertainTeed noiseproofing clip system:

Soundproofing insulation. Fill the wall cavities with soundproofing insulation like mineral wool or fiberglass. These materials absorb sound waves and reduce their energy.

Kraft-faced batts are friendliest to handle and easiest to fasten in place (a vapor barrier is not needed for interior walls). They should be installed tightly between framing members, and snugly around pipes, electrical boxes, wires, and heating ducts with as few hollows or gaps as possible.

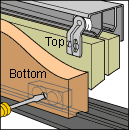

Multiple layers of drywall. Use two layers of drywall on each side of the wall for added mass and sound blocking. Consider using different thicknesses of drywall for each layer to further disrupt sound waves.

Green Glue: Apply Green Glue damping compound between the layers of drywall to enhance soundproofing performance. This is a like a super-thick, sticky glue that never fully hardens. It reduces vibrations and separates two layers of drywall. Available at home improvement centers or online, it costs from $2 to $5 per square foot of coverage. One tube typically covers 16 square feet. Apply according to label directions.

Mass loaded vinyl (MLV): Incorporate MLV within the wall assembly for exceptional sound blocking. It can be attached directly to studs or hung between layers of drywall. Mass loaded vinyl barriers offer a serious step-up in sound blocking. Made of high-density organic sands and salts, as well as minute metal particles, these 1/8 to 1/4-inch-thick products are sold in 4-by-8-foot sheets and 4.5-by-20-foot rolls. At about 2 pounds per square foot, they are heavier than they look.

The following video shows how to install Acoustiblock, one of the available MLV systems. Note: Some products are adhesive backed for easy installation.

Additional Tips for New Wall Construction

- Seal all gaps and cracks. Pay close attention to sealing around electrical outlets, switches, and any other penetrations in the wall with acoustical caulk or sealant.

- Use soundproof doors and windows. Choose doors and windows with high Sound Transmission Class (STC) ratings to complement your soundproof walls.

- Consider soundproofing the ceiling and floor. Sound can travel through ceilings and floors as well. Employ similar soundproofing techniques for these areas to create a comprehensive sound barrier.

By integrating these soundproofing techniques into your new wall construction, you can significantly reduce noise transmission and create a quieter, more comfortable living or working environment.

Conclusion

Soundproofing your walls, whether existing or new, requires a combination of strategic techniques and suitable materials. By understanding how sound travels and implementing the right solutions, you can effectively block unwanted noise and create a more peaceful sanctuary in your home.

Remember, every situation is unique. Consider the type and source of noise, your budget, and the level of soundproofing you want before embarking on any project. Consult with a professional soundproofing contractor if you have any questions or need assistance in choosing the best soundproofing approach for your needs.

With a little effort and the right knowledge, you can transform your living space into a tranquil haven where you can relax, work, and enjoy peace and quiet.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: