A detailed guide for buying lumber, including information about basic terminology and sizes

Of all the materials that go into building a typical house, the most prevalent is lumber.

In one form or another, lumber is normally used for the entire skeleton, plus wall, floor, and roof sheathings, finish floors, cabinets and shelves, and doors.

Wood that has been manufactured into cabinets, flooring, and other household materials is discussed under those subject headings throughout HomeTips. Here, you’ll find information on lumber and the various wood-based raw materials sold at lumberyards and home improvement centers.

It pays to brush up on basics before buying lumber. With the growing scarcity of wood, you can easily spend $2 to $3 per foot for what appears to be a plain board.

Understanding Lumber Terms

Knowing basic terminology will help you select the right materials and can save you a bundle.

Wood is classified as either softwood or hardwood, depending on whether it is from a deciduous tree (hardwood) or a conifer (softwood). Although most hardwoods do tend to be denser and harder than softwoods—oak and maple are much harder than pine, for example—these terms do not refer to the wood’s hardness. (Balsa, one of the softest woods, is a hardwood.)

The nature of wood differs by the part of a log from which it is cut. Heartwood, the older wood at the center of a log, is tighter grained and resists decay more readily. Sapwood, close to the bark, is more porous.

Species is the type of tree the wood is from: oak, Douglas fir, spruce, and so on. Different woods have different qualities. Redwood, cedar, and cypress heartwood, for example, are naturally resistant to decay. That’s why these woods are often preferred for outdoor use such as decking.

When wood is freshly cut, it is called green, or unseasoned. This terminology does not refer to the color. The term means that the wood has a high moisture content (20 percent or higher) because it hasn’t been dried yet. Although green wood is fine for some outdoor projects, it will warp, cup, and split as it dries. Kiln-dried (KD) lumber has been stacked and dried in a kiln.

Lumber is stamped with a moisture rating. S-GRN means it’s green. S-DRY indicates that it has less than 19 percent moisture. MC-15 means its moisture content is 15 percent or less.

Before lumber leaves a mill, it may be dressed so that it is trimmed smooth, or surfaced, on two or more sides. Most lumber is surfaced on all four sides (S4S). Unsurfaced lumber is usually referred to as rough.

Lumber is sorted and graded at the mill according to quality. Various grading agencies oversee this process, and the lumber is stamped with their identifiers. The factors that determine a board’s grade include knots and other imperfections. The more numerous the defects, the lower the grade. Because there are several different grading parameters, depending on the species, it’s a good idea to discuss lumber grades with the dealer. You should inspect each board for defects before making a purchase.

What Is a Board Foot?

No, a board foot does not appear at the base of a wooden leg. When you buy lumber in quantity, the price of a particular species and grade of wood is often quoted by the board foot, a measurement equivalent to one square-foot piece of wood that’s 1 inch thick. So, a 1-foot-long 1 by 12 is 1 board foot. Similarly, a 1-foot-long 2 by 6, which is twice as thick but only half as wide as a 1 by 12, is also 1 board foot.

Like the more familiar lineal foot pricing (where you pay according to the length of a piece) board-foot measurement does not account for the drying and surfacing of lumber.

Board-foot pricing allows a lumberyard to group several different dimensions—say, 2 by 4s, 2 by 6s, and 2 by 8s—under one price.

Understanding Lumber Sizes

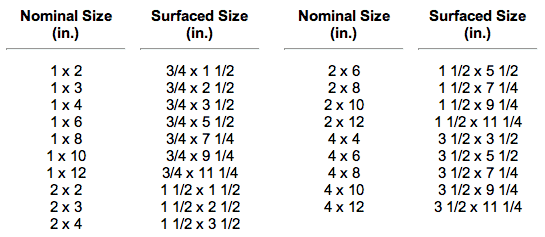

Surfaced lumber actually isn’t the same as its nominal size. In other words, a 2 by 6 is not 2 inches thick and 6 inches wide. After it has been dried and surfaced, it is actually 1 1?2 inches by 5 1?2 inches. The equivalents to nominal sizes are given in the chart below. Lumber is stocked by most dealers in lengths that range from 6 to 20 feet, normally in even increments.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: