Are you in the market for a new kitchen countertop? This expert guide discusses the various materials and options for you to consider.

Kitchen and bathroom countertops are made from materials that are durable and, in most cases, easy to maintain. From glass to stainless steel to concrete—just about any material that can provide a water-tight, durable, stain-resistant, handsome surface can be used for a countertop.

All of the varied countertop materials have distinctly different qualities, and some are far more durable, expensive, and/or difficult to install than others.

So, how do you choose?

Countertop Materials Overview

If you’re looking to install a new countertop, the material you choose will depend on your budget and the appearance and serviceable qualities you want.

Generally speaking, in order from least to most expensive, the following are the most popular. See the following pages for much more about countertop materials.

• Laminates are durable and made in hundreds of colors and patterns. However, they can be scorched by hot cookware and utensils, and they’re not suitable as cutting surfaces as they will scratch. Laminate countertops are made from a thin surface of high-pressure laminate that is applied to a base of particleboard or plywood.

• Ceramic tile is available in a vast array of colors and patterns and is extremely durable, easy to clean, and scorch-proof. Tiles are applied with mastic or, even better, mortar, to a plywood or tile backerboard base.

• Solid surface, a manufactured composite material, is quite durable and offers a seamless, easy-care surface that often imitates the look of natural stone such as marble, granite, or slate. Though solid surfaces can be machined with standard wood-working tools, installation requires a professional.

• Woods such as maple, oak, and other hardwoods, applied in butcher-block fashion, make handsome and durable countertops. Wood requires a finish to maintain its original patina, and it can warp, scorch, and foster bacterial growth.

• Natural stone such as granite and marble are considered to be the height of elegance and will last longer than most kitchens. Stone, however, is very expensive and requires some care: Grease will stain granite, and acidic substances such as orange juice will etch the finished surface of marble.

Countertop Basics

Standard kitchen counters are 24 inches deep and 36 inches from the floor. Bath counters are often shorter and shallower—30 inches high and about 18 inches deep. Some kitchen countertops have backsplashes-short vertical sections along the back that protect the wall.

Most countertops combine a base of plywood or particleboard that spans across the top of cabinets plus the finish surface material. They require the mastic, glue, mortar, or grout needed to adhere the surface to the base and keep it impervious to water and stains.

Edge treatments for countertops vary depending on the material. The square edge is the most common, particularly with laminates, wood, and tile. Bullnose is a safe, practical edge that makes a countertop look substantial.

Ogee is more decorative but can only be shaped from certain materials. A more decorative appearance can be achieved by a detail of wood, metal, or a different color sandwiched between layers of laminate, solid surfacing, or stone.

For a better understanding of the benefits and drawbacks of countertop materials, sort through each of the possibilities on the following pages. For information on countertops for outdoor kitchens, see Outdoor Kitchen Countertops.

Plastic Laminate Countertops

Plastic laminate countertops are manufactured using heat and pressure to combine layers of paper between two sheets of clear plastic, creating a tough surface that is then attached to a fiberboard or plywood backing.

The plastic protects the paper, which often has a decorative pattern and color, from scratches and moisture.

Used indoors from the bathroom and kitchen to the garage and laundry room, plastic laminate is a popular application because it is affordable, stain-resistant, easy to clean, and comes in a wide range of decorative choices.

The long list of options-from minimalist white to bold patterns and colors-continues to increase as design trends change. Today, plastic laminate can complement any decor imaginable due to its ability to also mimic other surfaces, including wood, stone, and metal.

As versatile as plastic laminate is, it has its drawbacks. It should not be used as a cutting surface, nor should hot pots be placed directly on it. Care should also be taken with cleaning fluids as certain chemicals can blister it. Minor blemishes can be fixed, but repairs may not blend in completely. Plastic laminate will also show the seam where two pieces meet.

Also keep in mind that all plastic laminates are not created equal, so choose carefully for the qualities that are most important to you. More-durable types are made with additional layers of paper between the sheets of plastic, producing a surface with greater impact resistance. Others are fire-retardant, chemical-resistant, or less likely to scratch. Still others hold color throughout, so scratches and seams are less visible.

Solid-Surface Countertops

Solid-surface countertops are popular for their durability and uniform appearance.

Made by mixing minerals and resins, the low-maintenance material is resistant to damage from heat, moisture, and fading.

Virtually unbreakable, solid-surface countertops can mimic the appearance of stone but have a warmer, softer feel, and they are much easier to repair if damaged.

Solid-surface material is also regarded for kitchen countertops and other work areas because of its versatility.

It can be manufactured to fit any space and can be molded into sinks, drainboards, and soap trays with ease. A wide range of colors and edging styles can be used to complement the design of any room.

Solid surface does have its drawbacks. It’s almost as pricy as stone, and the uniformity of color and texture can stress its artificiality. You’re also limited to using a certified contractor for installation or most manufacturers won’t issue a warranty.

Featured Resource: Get a Pre-Screened Local Solid-Surface Countertop Installation Contractor

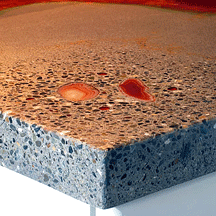

Concrete & GFRC Countertops

Concrete has moved indoors from driveways and front paths as a popular choice for countertops. Don’t picture a flat slab of gray concrete sitting on top of your kitchen cabinets, though-concrete can have a variety of finishes, from unembellished to sleek and modern.

For a textured look, the countertop can be embedded with marble fragments, glass chips, or even fossils. Concrete countertops can be shaped to fit any kitchen and can even be used to create different types of work surfaces such as cutting boards.

Concrete, which is made from cement, aggregate, and other additives, is a sustainable material. All its components are abundant and natural, making it an ideal option for homeowners interested in having a green lifestyle.

GFRC counter is a very strong composite made of Portland cement and glass fibers.

Concrete countertops do require more maintenance than traditional materials. Because concrete is porous, liquid can be absorbed and damage the surface. Especially damaging are highly acidic liquids such as vinegar, citrus juices, and wine. Although concrete countertops are sealed to prevent staining, the sealant may be broken down by heat or chipped by knives or other sharp implements.

Concrete is not flexible, so, as it settles, hairline cracks may appear in the surface. These are only superficial and will not affect the countertop’s durability or performance. If the sealant is kept in good condition, the cracks shouldn’t become discolored- depending on your aesthetic, they may even add to the appeal of the countertop.

Installing a concrete countertop is best left to a professional fabricator since the nature of the materials used to make up concrete require precise mixing and pouring to create the desired surface. In addition, every professional has his or her own proprietary method for finishing concrete countertops.

Professional fabricators can also properly reinforce the concrete, if it is necessary, with fiberglass, rebar, or wire mesh.

Ask around to find a reputable fabricator and then request references so you can judge the work for yourself. Be sure to ask how the fabricator reinforces and seals the concrete-the countertop should not need any support for at least 3 feet, and epoxy is generally the best (though most expensive) choice for a sealant.

If you are eager to pour your own countertop, there are kits available that come with the necessary materials and tools. However, you should do a test cast offsite so you can experiment with techniques and finishes before you start on your kitchen.

Glass Fiber Reinforced Concrete

While concrete has gained in popularity as a material for countertops, in recent years the need for more structurally sound, lighter weight concrete with greater design flexibility has arisen in the countertop materials market.

Enter glass fiber reinforced concrete (or GFRC). GFRC is essentially an ultra-strong composite made of Portland cement infused with randomly dispersed glass fibers that reinforce the concrete and increase its load-bearing capacity.

GFRC countertop and backsplash have stunning patterns.

One company, Absolute ConcreteWorks of Seattle, is on the front line of pre-cast GFRC technology. It produces an extremely lightweight yet durable material that can be used to create countertops as thin as 3/4 inch that, when cast and finished, require no grinding or polishing. Special edging or other treatments can be cast separately and integrated seamlessly.

A major difference between GFRC and traditional concrete is that GFRC allows for limitless design opportunities. For example, landscape elements from a customer’s property can be incorporated into the design-anything from fern leaves to tree branches to stones. All painted details are done by hand with rollers and sponges, and final touches are applied with intricate brushwork.

This technology goes hand-in-hand with the burgeoning industry focus on and consumer interest in “green building.” When a countertop is created, there is no waste-whatever material is left over is used for another project. And, the materials used to make the countertop are themselves easy on the environment.

The glass elements are from reclaimed or recycled materials, and the cement mix includes fly ash, which is the waste produced by industrial smokestacks. The finishes are also eco-friendly; these water-based materials give off no pollutants or toxins during production.

Stone Countertops

When it comes to durability and beauty, few countertop materials can compare with natural stone. And when it comes to elegance, granite, marble, and travertine take the top honors.

Here is a look at stone countertop materials:

Granite Countertops

Granite is a time-tested material that has been around for some 300 million years. Few surfaces match granite for its hardness and durability. It is also resistant to burns, scorching, and stains, although some varieties can soak in liquids if left to sit for an extended period of time.

Also, abrasive cleaners or those containing harsh chemicals should be avoided as their repeated use will cause the surface to dull. A sealer should be applied after installation and reapplied every one to three years.

Granite comes with numerous variations in color, pattern, and tone-qualities referred to as the stone’s “movement.” Varieties that have a fairly uniform speckled pattern are considered “consistent,” while “variegated” types have more disparate veins and swirls that give each slab a unique appearance.

It is important to note that no two samples of granite will have the exact same appearance. To get the best idea of what your countertop will look like, it is advisable to see the slab from which your countertop will be cut, not just a showroom sample.

Most granite countertops come with a high-gloss polish, but other finishes are available, offering a range of sheens and textures.

Marble Countertops

The rich tones and dramatic veining of marble make it an elegant, sought-after choice for kitchen and bathroom countertops. Colors include creamy whites, pinks, and beiges; mellow golds and oranges; and luxurious dark greens and blacks.

While marble is generally quite durable, it is, however, softer than granite and scratches more easily. Although it is fairly heat-resistant, intense heat can permanently discolor a marble surface. It is also highly reactive to acidic foods such as lemon and vinegar, which will destroy the polish, leaving dull spots. Marble countertops have to be sealed quite often to protect their surface from wear and tear.

However, you may desire the changing nature of marble over time; the eventual stains and evolving patina of the natural material may provide just the lived-in character you want. You may especially love marble if you bake a lot; marble is considered by professional chefs to be the perfect surface for rolling out pastry dough.

If you are choosing marble for your kitchen, request a honed finish-a slightly matte finish that will resist the etching and scratching that afflict a high-gloss finish that is subjected to heavy, daily use.

Travertine

Travertine lends a room a classic, Old World appearance. The stone comes in earth tones ranging from ivory to brown and is known for its textured, slightly pitted surface.

These pits, while offering character, can absorb liquids and trap food particles, eventually staining the countertop. Travertine’s softness also means it is more prone to etching and other abrasion. In addition, acidic substances can readily stain the surface.

To protect travertine from scratches, dirt, and stains, it can be honed to a slightly matte finish, its naturally occurring pits can be filled with grout or resin, and the surface can be sealed. While this is a high-maintenance countertop, particularly for a kitchen application, you may feel the aesthetic benefits of travertine outweigh the cons.

Though it is pricy, nothing beats natural stone as a countertop surface for elegance and durability. In addition to the popular granite, marble, and travertine, there are some lesser known but equally elegant stone materials:

Limestone

Countertops made of limestone typically come in a beige color with little crystals that provide visual interest. Some countertops are even embedded with tiny fossils. Limestone has long had a bad reputation for staining and eroding, but if you buy from a reputable dealer you will get a countertop made of dense limestone that is nearly as stain-resistant as granite. As with all stone surfaces, most stains-even red wine-can be removed using an oxygen cleaner.

Soapstone

The subtle, gentle appearance of soapstone has been appreciated for hundreds of years, not just for countertops but sinks as well. It resists stains and damage from acids and even retains heat (making it an excellent sink material). Though strong, it is surprisingly easy to cut with carpentry tools. It is fairly easy to chip or scratch soapstone, but you can usually repair the damage using fine sandpaper and elbow grease. Because it naturally resists bacteria, there is no need to seal soapstone.

Lava Stone

This is a very high-end material, made from volcanic lava stone that is glazed with enamel and then fired in a kiln to produce a glossy surface. The result is as smooth and slick as an enamel cooking pot.

Slate Countertops

Available in a wide variety of densities, the slate that is used for countertops is among the densest, but it is still softer than granite and even marble. It comes in shades that include gray, black, green, and rust. Like soapstone, it is soft and susceptible to scratching, but it also can be repaired fairly easily. Slate may be highly polished or left with a matte finish for a rustic look.

Natural Stone Tile

If you want the look of natural stone for a fraction of the cost of a granite slab, consider installing stone tiles. The resulting countertop will not have the massive appearance of a slab, but it will have all of the same visual interest. And, if properly installed, it will be nearly as smooth as a slab.

Granite is the most popular stone choice for kitchen countertops due to its strength and stain-resistance. You can also use any type of stone tile made for flooring, but ask your dealer about its stain-resistance and whether or not you will need to seal it.

Polished tiles 12 inches square make a good choice for a kitchen countertop, which is typically 25 inches deep; check your base cabinets to be sure the countertop will overhang them by at least 1/2 inch. You may choose to install a fairly thick backsplash in order to bring the tiles out farther.

At the front edge you have a number of options:

1) You could cut 1-inch-wide pieces of the tile and tuck them under the edges of the surface tile. If you do this carefully, the appearance can resemble a thick slab. If the face of the tile is polished but the edge is not, pay a fabricator to polish the edges, or apply several coats of clear lacquer to the edges.

2) You could install decorative wood trim about 1/16 inch below the surface of the tiles. But be sure you have plenty of fastening surface in the countertop substrate. If possible, fasten the trim with a biscuit joiner so there will be no visible fastener heads.

3) Or, you could install ceramic or stone bullnose or V-cap tiles of a color that harmonizes with the field tiles.

Ceramic Tile Countertops

Ceramic tile, made from a mixture of clay and other all-natural elements, has been used as a surfacing material for hundreds of years. In fact, it is very little changed in make-up from what it was a thousand years ago.

Classic ceramic tile countertop is supremely durable and available in a world of options.

Ceramic tile comes in a vast array of colors, textures, and finishes, making it an ideal choice for almost any decor-from traditional to avant-garde.

Because of its water and stain resistance, it has long been the most popular countertop material for kitchens and baths, particularly the glazed variety. Glazed ceramic tile is made by baking the glass-like glaze onto the tile, which gives it a hard, protective shell.

Another popular tile for countertops is ultra-tough porcelain. Made by baking white clay at high heat, porcelain is more expensive than ceramic tile but also completely resistant to water. It can be tinted almost any color, but look for tiles that are tinted throughout, which will make any chips far less noticeable.

Any tile that is not glazed, which means it was fired at a comparatively low heat, is not a good choice for a kitchen. The tile is porous, so it will soak up water and other liquids. This will not only stain the tile but also create a breeding ground for bacteria and mildew.

Tiles come in a wide array of shapes and sizes, from the standard 4-inch-square field tile to such specialized shapes as octagons and even rhomboids. An increasingly popular choice for countertops is 12-inch floor tiles, which make for a flatter surface and fewer grout lines.

The choice of design statements is also vast. Tiles come with metallic glazes, hand painting, embossed designs, and finishes that mimic natural stone. You can arrange tiles in a multitude of ways, mixing colors and sizes in checkerboard, mosaic, or random patterns.

Versatile as tile is, it does have some drawbacks. It can chip and crack, and you may need to re-grout every few years if the grout becomes stained or cracked.

The cost of tiles is just as varied as the tiles themselves. A standard field tile by a major manufacturer can cost as little as 35 cents, while custom handmade tiles can run as much as $150 apiece. If you get your heart set on a particular tile but budget is a concern, think about combining standard field tiles with a few hand-painted tiles as a backsplash. (Avoid using decorative tiles on a countertop because they are not water resistant.). You can also save money by doing the installation yourself.

Wood and Richlite Countertops

Wood is a versatile, durable, and warm material for kitchen countertops and other work surfaces. Depending on the look you want, wood countertops can be sleek and modern or natural and subdued. With its many finishes and grains, wood works beautifully into many interior design plans and can soften the feel of other materials such as metal and stone.

Wood countertops can be cut to fit any kitchen or other workspace indoors or out. The resilient surface helps protect dropped china, and minor damage to the wood is easily repaired.

Different types of wood are better suited to different types of work spaces. For kitchens, maple butcher block is ideal-it’s hard enough to stand up to cutting and chopping but not so hard that it’ll dull knives. And, any nicks and cuts only enhance its personality. The best butcher blocks are made from 4-inch-thick end-grain pieces connected parallel to one another with finger joints.

A butcher block can be installed into or around an existing countertop made from a different material. An unfinished butcher block needs to be sanded, filled, trimmed, and edged; however, finishing it yourself can save significantly over the purchase of a finished one. Butcher blocks can also be made from exotic woods such as teak, cherry, mahogany, and walnut, but, because they’re expensive, you want to treat them more delicately than you would maple.

For outdoor work surfaces such as potting or work benches, choose woods that resist insects and moisture; fir, cedar, redwood, and teak all fill the bill. If you’re planning on using a surface to serve food or handle edible plants, stay away from pre-treated wood and avoid using toxic chemicals to stain or seal it.

Soft woods such as poplar and pine should be kept to indoor use because they can become weather damaged. Lower-quality softwoods can be painted and sealed with varnish.

Wood does have some disadvantages. It’s not heatproof, so you’ll need trivets-either freestanding or built into the countertop-on which to rest hot pots and pans. If the wood is untreated, it will also absorb moisture, which will not only stain but also create a perfect environment for bacteria to thrive. Regularly staining or oiling wood and cleaning it thoroughly after food preparation are the keys to maintaining a safe, beautiful kitchen countertop.

Richlite Countertops

A lower maintenance countertop alternative to wood is Richlite, a composite product that’s nonporous and resembles wood. Richlite is made with paper-based fiber from sustainable hemp fields or forests and produces no hazardous waste during the manufacturing process, making it an eco-friendly option.

The biggest advantage to Richlite is its strength-it can extend out far past a support without sagging or snapping. For example, a 1-inch-thick piece can extend out 18 inches; the thicker the piece, the further it can extend. This stability makes Richlite an ideal material for countertops that incorporate an eating counter.

Richlite countertops come in a range of matte-finished colors that, like wood, will darken over time with exposure to natural light. It’s heat- and water-resistant and will resist stains if it receives regular applications of sealant.

Sharp objects can scratch Richlite, but, since it’s colored throughout, most marks are inconspicuous and can be buffed out. However, gouges can’t be repaired.

Metal Countertops

Specialty shops can custom-fabricate metal countertops to most any shape. You can choose an integrated sink for a seamless surface that is easy to wipe. Or you can choose to add decorative ribs or dots. A dish drainer area can be sloped so water drains into the sink.

The most common choices for metal countertops are stainless steel and copper, though other metals are available. They come in a range of thicknesses; the thicker the metal, the quieter and more resistant to denting it will be.

Stainless-Steel Countertops

A countertop made from stainless steel matches the look of many high-end appliances, such as ranges and refrigerators, and so may be a good decorator choice. Unlike other metals, stainless won’t oxidize and develop a patina, and it doesn’t need to be coated with a finish. It is difficult to scratch and resists denting.

Stainless steel comes in different grades with finishes that range from glossy to a dull, brushed look, so consult with your supplier to choose the type that matches your decor and is easy to clean.

Copper Countertops

When it comes in contact with water and air, copper oxidizes, resulting in a darker brown or greenish color. You may choose to polish it weekly to keep its color pristine or treat it more casually and enjoy a somewhat mottled appearance or patina.

Copper has anti-bacterial properties, and some studies have shown that it kills E. coli bacteria in a matter of hours (E. coli can live for a month or more on most countertops).

However, copper is easily dented and scratched.

Zinc Countertops

This old-fashioned material is sometimes seen in farmhouses and seafood restaurants. It is not universally available, but you can find it in certain regions. Zinc is fairly soft though not quite as easily scratched as copper. You can choose to polish it weekly or allow it to mellow into a mottled blue-gray color.

Pewter Countertops

An American tradition, pewter is an alloy of tin and copper or other metals. Older pewter contained lead, but newer types are lead-free for safety reasons. Like copper and zinc, pewter will change color if not regularly polished. Depending on the type of alloy, it may become deep gray or even nearly black. Its ability to resist scratches and dents will also vary according to the alloy.

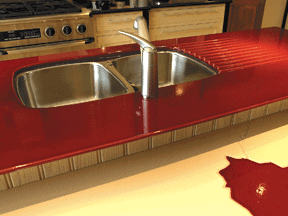

Glass Countertops

For durability, ease of maintenance, and sleek sophistication, nothing beats the many virtues of glass. A longtime favorite for desk and table tops, glass is now gaining in popularity as a countertop surface.

Considering its simple elegance, it can complement almost any type of home decor. Glass left clear will go with any color scheme, or, one side can be painted to match or contrast with a room’s predominant color. Etching or sandblasting, curving or beveling the edges, will also lend visual interest.

Glass is generally manufactured in rectangular sheets anywhere from 1/4 to 1 inch in thickness.

Artisanal glass is hand- and custom-made to specification.

During installation, glass can be easily cut to accommodate any configuration.

Though glass can chip or even break with a large enough impact, its virtues are that it is impervious to heat and stains, making it a good choice for both kitchens and baths.

On the downside, glass can scratch, and it is difficult to keep free of fingermarks, which even clean hands can leave. In addition, though cleaning up messes is easy, any residual water left on the surface can leave permanent water marks.

Featured Resource: Get a Pre-Screened Local Laminate Countertop Installation Contractor

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: