This guide will teach you how to use a circular saw and saber saw (jig saw) safely and effectively. Learn how to cut perfectly straight lines with a circular saw, and smooth curves and cut-outs with a saber saw.

Cutting Straight with a Circular Saw

Cutting with a Saber Saw

A power circular saw allows you to make straight crosscuts much faster than you could ever do with a handsaw, and it is unparalleled for ripping along the lengths of boards. Common sizes are from 5 1/2 to 8 1/4 inches, which refers to the largest diameter of blade that will fit the saw’s arbor (also called an axle).

The most common, the 7 1/4-inch model, will go through surfaced 2-by framing lumber at any angle between 45 and 90 degrees. Look for a model rated at between 8 and 12 amps.

Cutting Straight with a Circular Saw

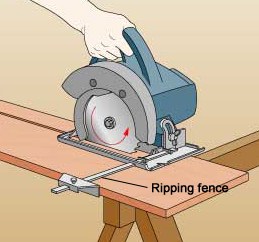

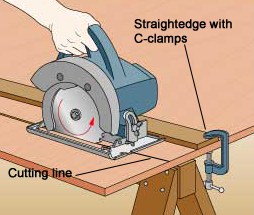

To cut straight with a power circular saw, either use the ripping fence that comes with the saw or fasten a straightedge to the surface you’re cutting, as shown in the illustrations below.

For the latter approach, measure from the saw’s base plate to the blade, and secure the guide that distance from your cutting line.

Cutting with a Saber Saw

The saber saw’s high-speed motor drives one of many types of blades in an up-and-down (reciprocating) motion; the blade on an orbital model goes forward and up and then back on the downstroke for faster cuts.

The tool excels at cutting curves, circles, and cutouts in a variety of materials, but you can also use it for straight cutting or beveling. Consider a variable-speed model for greater control on tight curves and different materials.

Choose the right blade for the job. Blades with 4 to 7 teeth per inch (tpi) are designed for rough, rapid cuts in wood. Fine finish work, tight curves, and scrollwork require blades in the 10 to 20 tpi range.

For thick metals, use 14 to 18 tpi blades; thin metals demand even finer teeth (24 to 32 tpi). Specialty blades also are available to cut other materials.

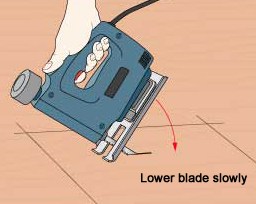

To make a cut-out, drill a hole for the saber saw’s blade in the waste area, or, if it is a thin, soft material, “plunge cut” with a rough-cutting blade. Rock the saw forward onto the front edge of the base plate until the blade is free at its full extension.

Turn on the saw and, with the nose of its base planted solidly, lower it slowly until the base sits flat on the surface. Then cut normally.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: