Expert advice on how to take apart bathroom faucets, with illustrated diagrams of how a compression, ceramic-disc, ball and cartridge faucet works.

Compression-Style Faucet

Ceramic Disc Faucet

Ball-Style Faucet

Cartridge Faucet

TOOLS & MATERIALS FOR FAUCET DISASSEMBLY AND REPAIR

| Tools | Slip-joint pliers Allen wrench (hex wrench) Adjustable wrench Screwdrivers |

| Materials | Faucet washers O-rings Inlet and outlet seals Replacement discs or cartridges |

Do you need to disassemble a bathroom faucet to repair it? If you do, this guide should help.

For complete step-by-step guidance on faucet repair, see How to Fix a Leaking Faucet.

Here’s how to disassemble a faucet:

- Turn off the water supply valves under the sink.

2. Place a towel in the sink to prevent scratches and to catch any dropped parts.

3. Remove the handle. To do this, use a small, flat screwdriver to pry up the decorative cap, button, or plug at the top of the handle, used to hide a screw. The method for removing this can be a bit of a mystery, depending upon the faucet manufacturer. If you can’t find a tiny, hidden screw or fastener, the chances are pretty good that you just pry it off.

4. Unscrew the screw that holds the handle and pull or pry off the handle.

5. Lay out the parts in order as you remove them so you won’t have trouble re-assembling the faucet. And be sure to note the manufacturer’s name on the faucet (if you can find it) and take the old parts with you when you go to buy replacements. If you have the name of the manufacturer, you might also be able to search online for the manufacturer’s instructions for that particular model.

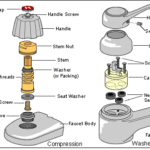

Compression-Style Faucet

Among the various faucet tap technologies in use, compression-style faucets have been around the longest. They are also the least expensive type.

Compression faucets have two separate handles. When the handle is turned, it raises or lowers a washer or seal that closes against a valve seat at the base of the stem to restrict water flow through the faucet body when you turn the handle off.

The use of a washer to make the seal is actually pretty old-fashioned in comparison to modern faucets, but it’s the type that you often find in an older home.

The fundamental problem with a compression faucet is that the rubber washer or seal wears out over time. When this happens, the tap drips or drools.

Some newer types of compression faucets lower and raise the washer without grinding it into the valve seat. For example, American Standard’s economy NuSeal faucets lower and lift the rubber washer vertically without rotating it. Because it doesn’t grind the washer against the seat, the washer lasts longer.

Unscrew the bonnet from the faucet base, using slip-joint pliers. Then remove the valve stem; this has reverse threads, so unscrew it by turning it clockwise. Once you have it out, replace all rubber washers and O-rings.

Ball, cartridge, and ceramic-disc faucets, known as being “washerless” faucets, don’t use washers for the off-and-on action, though they do have O-rings and neoprene seals to prevent leaking.

Ceramic Disc Faucet

Most ceramic disc faucets don’t drip or leak because they’re made to be almost maintenance free. Two ceramic discs regulate the flow of water: a movable upper disc turns or lifts and lowers against a fixed lower ceramic disc. The seal between the two discs is watertight because they are polished to near-perfect flatness.

Ceramic disc faucets were first made popular by high-end European faucet makers and now produced by American Standard, Kohler, Price Pfister, and many other American faucet manufacturers.

Ceramic disk faucets are nearly maintenance free and are generally guaranteed not to wear out. Ceramic valves are more durable over the long run in a broader variety of water conditions than any other variety of valve on the market.

The discs themselves have diamond-like hardness—they are impervious to line debris, mineral buildups, and other common problems that affect valve life.

If this type of faucet leaks, the culprits are usually the inlet and outlet seals or sediment buildup in the inlets. The handle should be in the “on” position when repairing a disc faucet to prevent cracking the replacement seals.

If a peeling from galvanized pipe or a small rock gets into the valve, it can score the surfaces, but these occurrences are rare. If a ceramic disc faucet drips, don’t try to force the handle closed—just flutter it back and forth a few times to dislodge any particles.

Ball-Style Faucet

Ball faucets have a single lever that operates a rotating, slotted metal ball. The slots in this ball align with hot and cold water inlet seats in the faucet body to regulate the amount of incoming water allowed to reach the mixing spout.

Delta is one of the primary manufacturers of this faucet type.

Remove the decorative cap and screw to pull off the handle. To tighten the plastic adjusting ring inside the cap, you turn it with a special flat adjusting tool (or fit two screwdrivers into the slots and cross their blades to turn the ring.

For a spout leak, unscrew the cap, using locking-jaw pliers (wrap the jaws with duct tape to prevent scratching the faucet’s finish). Lift out the ball, and replace the rubber seats and springs on both sides of the valve.

If the faucet leaks around the spout, replace worn O-rings.

Cartridge Faucet

Cartridge faucets have a hollow metal or plastic cartridge insert that seals against the spout or faucet body. Depending on how a series of holes in the cartridge align with the stem, water is mixed and controlled. Drips usually mean the cartridge needs replacing.

Cartridge faucets are referred to as “washerless” because they control flow using methods other than a washer and valve seat (though they do have O-rings and seals to prevent leaking). Water flow is controlled by an up-and-down movement of the cartridge; to change water temperature, you just rotate the handle.

Remove the decorative can and screw and pull off the handle. To release the cartridge, use a pair of pliers to pull the retainer clip straight out. Pull out the cartridge and replace the O-rings and seals to fix leaks.

If the faucet drips, you may need to replace the entire cartridge.

How Faucets Work FAQs

- Can you fix a faucet by yourself?

Yes, you can fix a faucet by yourself if you have the necessary tools, a little DIY experience, a basic understanding of plumbing mechanics, and can follow step-by-step instructions for the specific type of faucet you have.

- How costly can it be to fix your faucet?

If you plan to DIY the repair, you can buy replacement parts for most faucets for less than $50—in fact, many parts like faucet washers are less than $10. Some replacement discs and cartridges can cost up to $150, however. Plumbers typically charge $65–120 per hour.

- What tools are required to fix your faucet?

Fixing a faucet typically requires basic tools such as an Allen wrench (hex wrench), slip-joint pliers, screwdrivers, and wrenches, but the exact tools needed may vary depending on the type of faucet you are repairing.

- How do you determine that your faucet needs fixing?

A faucet needs fixing when there are signs of leaking, dripping, reduced water flow, or strange noises during operation, indicating that parts may be worn out or damaged. If a faucet is more than 5 years old and a simple fix doesn’t do the job, replacement is usually the better option.

- What are the safety precautions required before I start fixing the faucet?

Before starting to fix a faucet, make sure the water supply is turned off! Otherwise, the area will become flooded when you disassemble the faucet.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: