Expert advice on how to layout and build stairs—or how to buy pre-manufactured staircases. Includes videos on how to layout and cut stair stringers, how to size stair treads, and building codes for stairs.

Any house built with more than one level has at least one staircase that serves as its vertical thoroughfare. There are, of course, many different kinds of staircases, differing by their materials, construction methods, general shape, design, and features.

In most situations, a staircase is an integral part of a home’s design and style. Stairs may be steep or gradual, narrow or wide, purely functional or grand and showy.

Some are built in place by woodworkers, finish carpenters, or stair makers. Others are factory manufactured, shipped to a building site, and installed by carpenters.

A stair’s design is heavily affected by its function. A highly visible entry stairway that handles all up-and-down foot traffic is bound to be much grander than a rarely-seen stairway to a basement.

The Parts of a Staircase

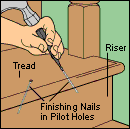

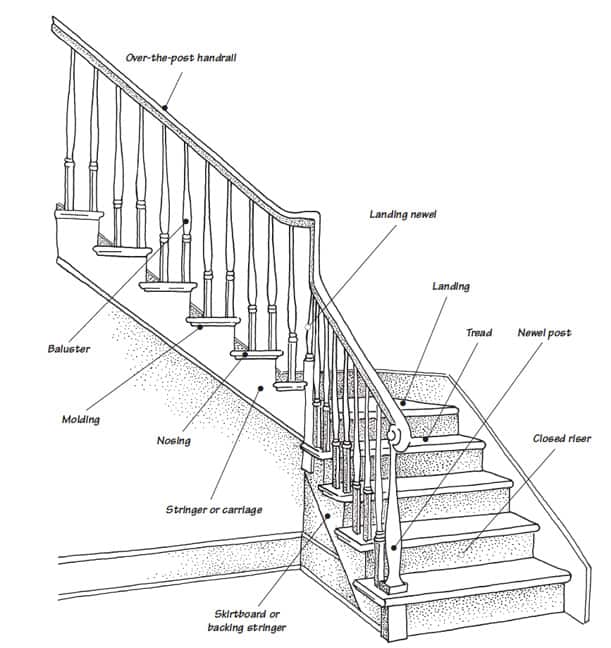

Regardless of type, all stairs have the same fundamental parts, as shown in this illustration.

It is how these parts are built and combined that gives a stairway its style and individuality. Of course, not all stairways have all of these parts. For example, some stairways have open risers.

The form a staircase takes is determined by the home’s design, the builder’s skill, the amount of space available, and the budget.

Staircase Building Codes

Stairs are built according to basic rules and principles intended to make them safe to use. Because the location of railings and balusters, width and depth of tread, and height of risers affect the ease and safety of using a stair, these dimensions are regulated by building codes.

You must be sure that any stair you plan, build, or buy will meet your local codes. Though many local codes are based on certain national standards, there is no single national code that regulates stairs in all areas. Some local codes have different restrictions than accepted standards because of local conditions such as danger of flooding or earthquake. Get your local stair-building requirements from your city or county building department.

As a general rule of thumb, the International Code Council, administered by the Building Officials and Code Administration (BOCA), may allow maximum riser height of 7 3/4 inches and a minimum tread depth of 9 inches plus a 1-inch nosing where solid risers are utilized. Even if 7 3/4-inch risers and 10-inch treads are allowed in your area, we suggest opting for shorter heights and deeper treads for the sake of comfort and safety.

These dimensions are a revision of earlier, briefly adopted standards that allowed a maximum of 7 inches on risers and a minimum of 11 inches for tread depths-sizing promoted by some safety experts following a 1985 study of accidents on stairs in the workplace. Despite the fact that the steeper stairs are acceptable to many codes, some experts believe they are prone to cause more accidents. Some builder organizations argue that these claims are yet to be proven and that 7-11 stairs take up more space and increase the costs of building them.

When planning or ordering stairs that turn, such as spiral stairs, pay special attention to exactly where on the steps your measurements must be taken for code acceptance. Many codes demand a 9- to 10-inch tread depth (minimum) at a point 12 to 14 inches from the narrow side. You’ll also find restrictions on head-height clearance and railing construction and placement.

The key is to be sure that any stair you buy will not only meet your local codes but, be will also be an attractive, safe, easy-to-use addition to your home.

Planning Stair Types & Shapes

Determining where to locate a staircase and the right type and shape of stairs to install can be challenging. If you’re doing new construction, where design possibilities are limitless, stair location and type should be worked out by a trained interior designer or architect during the space planning phase of developing construction drawings.

If, on the other hand, the scope of your project is smaller and the location of your new stairs is pretty much a given, you’ll obviously have a narrower set of options. Available space is key to determining a stair’s shape.

Stairs may be spiral, straight, circular, or any of several other shapes. And, of course, they may be wide or narrow, steep or gradual (within code limitations). As a general rule, the wider the stair and more subtle the climb, the more inviting the staircase—but also the more floor space it will consume.

A straight staircase that ascends directly from one floor to the next is the easiest (and usually the most affordable) to build but can be somewhat formidable to climb.

Stairs that stop at a landing and turn 90 or 180 degrees take up less space and can be safer and easier to traverse. Because of this, stairs with a landing—L-shaped or U-shaped stairs—are often preferred where space allows.

A spiral staircase takes up the least amount of space and is economical to install, but it is also the hardest to climb. This type of stair is particularly impractical when you need to carry large objects from one floor to the next, and it is not safe for use by children or the elderly. Homes with a spiral stair often also have another stair that provides easier access for moving furniture and similar needs.

A circular stair is elegant and welcoming to climb. It is also one of the most expensive and difficult types of stairs to build.

How Stairs Are Built or Bought

Most types of stairs are built on site by carpenters, but you can also buy certain styles pre-made.

During construction or remodeling, carpenters typically build the basic stairs from framing lumber and plywood. Then finish materials, such as carpeting or oak treads, are applied.

A finish carpenter installs handrails with ornamental balusters, newel posts, handrails, and the like. Most of these parts can be purchased pre-made and then customized as needed for a particular stair. For a staircase that ascends between two walls, a simple railing is typically attached to the walls.

Some manufacturers build conventional hardwood stairs in sections, ready to connect end-to-end or at landings.

Stair systems are manufactured as unfinished, shop-assembled sections that can be installed by two workers with minimal carpentry tools. Stock stair and railing designs range from Colonial to contemporary. Most stairs cost from $1,000 to $2,000, but for custom-designed products, the sky is the limit.

With most pre-built hardwood stairs, the newel posts, railings, and balusters are pre-cut, pre-fitted, and numbered for easy reassembly. Visador-Coffman Stairs has gone one step further with pre-assembled railing sections that can adjust to the slope of any stair.

Mylen Stairs manufactures stair systems that have a contemporary, open look, with stair treads held only by single or paired stringers. Steel stringers are pre-welded to support oak, pine, or mahogany treads. You simply bolt the stringers to the header and floor and then bolt the treads to the stringers. Balusters bolt to the treads and handrail.

How to Layout and Cut a Stair Stringer

One of the most confusing tasks when building a stair is laying out and cutting the stair stringers—the angled beams that run from lower to upper floors and are notched to carry each stair tread. This job is actually a lot easier than it looks when you know how to do it.

This video does a good job of showing you how to make a simple template for measuring and marking stair stringers.

How to Buy Spiral Stairs

Of the many available pre-built and knock-down stair kits, spiral stairs are by far the most prevalent, no doubt because they’re relatively economical in cost and space usage and because they can provide alternative access away from the central “staircase core” of a house. Spiral stairs are ideal for reaching attic or basement rooms and for two-story additions. They are also a popular choice for secondary access to rooms.

Manufacturers make spiral stairs in steel, aluminum, hardwoods, and combinations of these materials. Although some specialize in making only hardwood or metal, many companies make both. They typically offer a few basic designs that can be customized by selecting from a smorgasbord of treads, balusters, railings, and other options.

The range of options is vast. Hardwood stairs come in red oak, poplar, white oak, ash, walnut, mahogany, cherry, and other species. Steel and aluminum stairs come in a variety of finishes, from hot-dipped galvanized to custom color coatings. Treads may be flat or embossed steel, gratings, hardwood, rubber, or plywood, or steel base for carpeting. And so on. Boston Design Corporation even offers “illuminated stairs”—with one model, low-voltage lighting is radiated from the column under 3/4-inch frosted tempered glass treads.

When ordering a spiral stair, you usually choose the direction of twist (right hand railing up or left hand railing up) and you always specify the diameter. Most manufacturers offer several standard diameters: 4 feet; 4 feet 4 inches; 5 feet; 5 feet 4 inches; 6 feet; 6 feet 6 inches, and larger (for safety, stairs 4 feet in diameter and smaller are not recommended).

One key choice you must make when selecting a spiral stair is whether to buy a knocked-down kit or a complete one-piece unit. Though kits are cheaper and considerably easier to ship, one-piece stairs tend to be more durable, are less likely to come apart or rust because they have fewer joints, are lighter in weight, and can be installed in as little as ten minutes compared to three or four hours for a kit.

One-piece units also afford a much broader choice in materials—particularly railings—because they’re not constrained by the need for easy disassembly and shipping. Many kits, for example, come only with flexible vinyl railings.

Kits start at about $400 for small-diameter, standard steel models. One-piece steel stairs start at about $500. Aluminum stairs are lighter to ship, but the material is much more expensive—they start at about $1,500. All-wood or metal-and-wood stairs run from $2,000 to $5,000 or more.

A spokesperson for Stairways, Incorporated, a manufacturer of both kits and one-piece units, estimates that freight from the company’s Houston factory to New York would run about $160 for a kit or about $400 for a one-piece stair. Of course, if you intend to hire a couple of workers for three or four hours to install a kit, freight savings can be quickly swallowed up by labor costs.

Spiral Stairs of America ships completely assembled one-piece welded spiral stairs from its plant in Pennsylvania to “anywhere a truck or cargo ship will go,” says a company spokesperson. For destinations where freight of a complete unit would be prohibitive, the company also sells stairs that are disassembled into two or three sections.

How to Buy or Build Circular Stairs

Most circular stairs are custom designed for high-end houses and installed during house construction by a talented stair builder.

Some come as completely pre-assembled units. A.J. Stairs, for example, builds fine-quality hardwood stairs from any of several different hardwoods and ships them to the job site on a company truck with a factory-trained driver who supervises the installation, which takes about an hour. Curved walls are built by the job carpenter after the stair is installed.

Others, such as custom designs by Duvinage, are built at the factory and then disassembled into three or four large sections for shipping. Both these and one-piece circular stairs are extremely heavy and require a crane or some other type of lifting device at the job site.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: