This illustrated article shows how basic interior wall–framing components are assembled, including wall studs, drywall, plaster, and panels

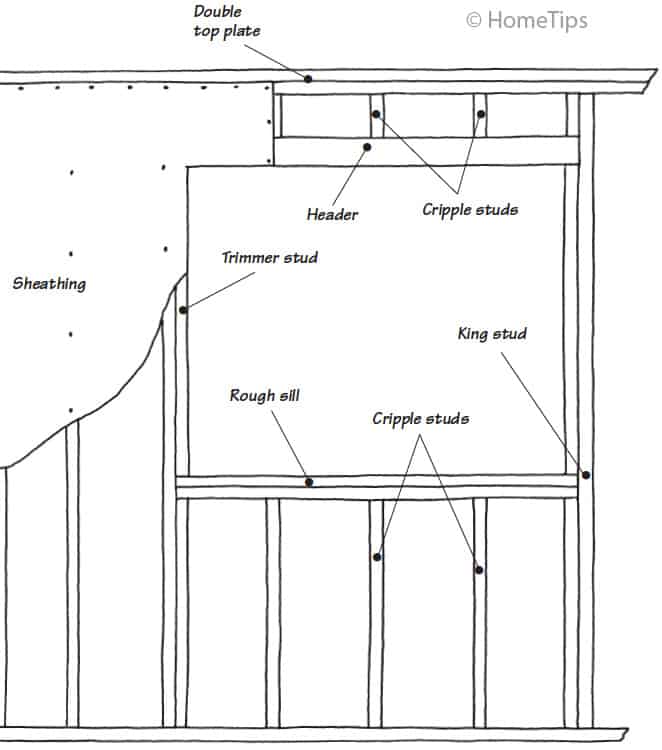

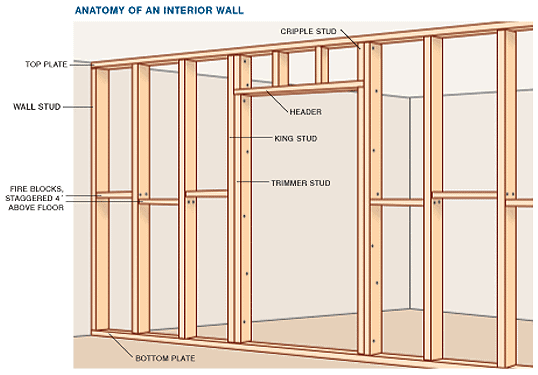

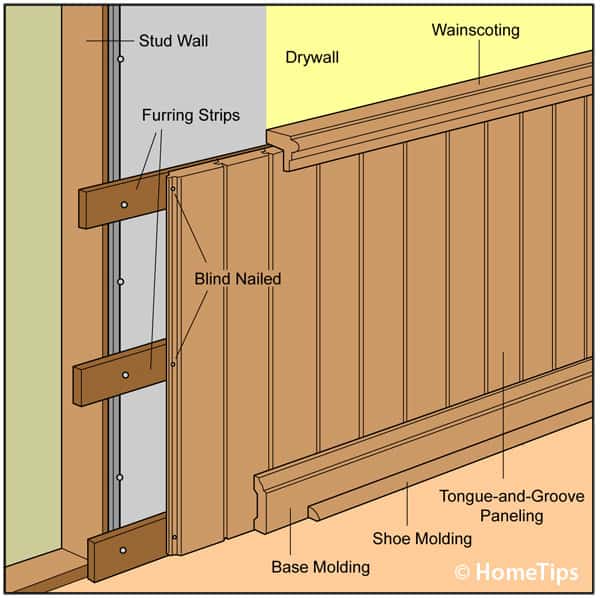

In the illustration below, you can see an interior wall’s basic wall-framing components.

Wall studs, typically spaced 16 or 24 inches from center to center, are the vertical supports that run from top to bottom.

Along the floor, a bottom plate serves as a base; a top plate does the same across the ceiling. Both plates are nailed to solid framing.

At openings, wall studs are doubled at each side, and a header spans the top of the opening. Fire blocks run horizontally across the center, adding support and a nailing backer for wall-covering materials.

TOOLS AND MATERIALS FOR WALL CONSTRUCTION

| Type of Wall | Tools | Materials |

| Wall Framing | Carpentry tools such as hammer, tape measure, level, power circular saw | 2×4 or 2×6 wall studs, bottom plate, top plate, fire blocks, and nails |

| Drywall Construction | Wallboard nails, wallboard screws, tape measure, level, utility knife, taping knife, screw gun | Drywall panels and nails or screws, joint tape, and joint compound |

| Plaster Wall Construction | Trowel, hawk, mixer, sponge, float, hammer | Plaster, lime or gypsum, sand, water, lath or mesh, nails |

| Interior Wall Paneling | Carpentry tools such as hammer, tape measure, level, power circular saw | Wood paneling sheets or boards, drywall (if required as backing), moldings, nails |

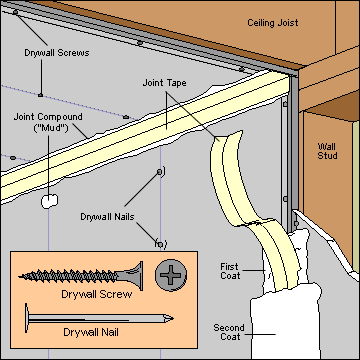

Drywall Construction

Drywall panels are fastened directly to wall studs or to furring strips applied over masonry surfaces using wallboard nails, wallboard screws, or, in some cases, adhesive. The joints between panels are hidden by wallboard joint tape and joint compound. In some cases, a special topping compound is applied over the entire surface.

Drywall is the most common of wall-covering materials. For complete directions on how to work with drywall, see How to Cut Drywall (Sheetrock) and How to Attach Drywall (Sheetrock).

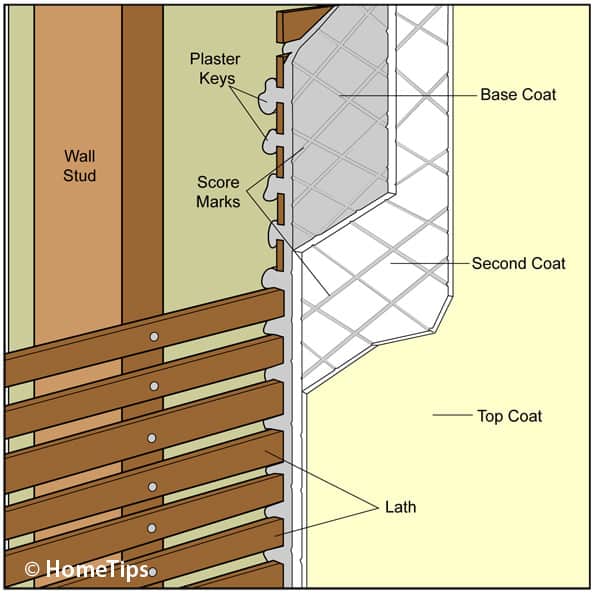

Plaster Wall Construction

Plaster is made from lime or gypsum, sand, and water and is one of the oldest building materials still in use—in fact, plaster applied to the Egyptian pyramids 4,000 years ago still holds its integrity.

Today, plaster is applied in three layers: a base coat, a thick coat of plaster for strength, and a finishing coat.

Plaster can be applied to many surfaces, including wood lath, metal mesh, wallboard, or masonry.

Some homes may even have ornamental plasterwork formed by hand or cast in molds and applied to walls and ceilings. Plaster can be applied in decorative patterns such as swirls and peaks.

Plaster can be painted or pigment can be mixed into it before it is applied. Such decorative treatments as wallpaper and tile can be easily applied over plaster.

Interior Wall Paneling

Many homes have wood paneling that covers all or part of a wall in a living room, study, family room, or similar space.

Sometimes paneling is paired with another material on a single wall—for example, it isn’t unusual for the top of a wall to be drywall and the bottom half to be wood paneling, or wainscoting.

Wood paneling is typically installed as solid boards milled to overlap or interlock with tongue-and-groove or shiplap edges.

Wood paneling is also sold in 4-by-8-foot sheets that are fairly thin, normally 1/4 to 3/4 inch thick. These sheets can be made from different kinds of hardwood that can be given a clear finish, less expensive woods that are meant to be stained or painted, or a wood-veneer or simulated-wood material.

Paneling may be applied to drywall, directly to wall studs, or to furring strips applied over masonry surfaces.

In many areas, building codes require installing wood paneling over a backing of drywall that is fire-resistant.

How Walls Are Built FAQ

- How do you build a wall, step by step?

1. Measure and plan the wall location.

2. Install the top and bottom plates.

3. Cut and secure the studs between the plates with nails or screws.

5. Add insulation, electrical, and plumbing if needed.

6. Cover with drywall or chosen wall material.

- How is wall framing done?

Wall framing involves building a skeleton for a wall, using vertical wall studs and horizontal plates. The top plate is attached to the ceiling, the bottom plate is secured to the floor, and studs are spaced evenly between the bottom and top plates, forming a rigid frame.

- How are interior walls framed?

When building a 2-story house, the two types of wall framing are platform framing and balloon framing. Platform framing involves constructing one floor at a time, with wall sections built on top of the completed floor. Balloon framing uses continuous studs that run from the foundation to the roof, supporting multiple floors.

- How is an internal wall built?

An internal wall is built by establishing a frame with a top plate attached to the ceiling, bottom plate fixed to the floor, and studs placed between the two at regular intervals. The frame is then covered with materials like drywall or plaster to form the finished wall.

Don Vandervort writes or edits every article at HomeTips. Don has:

Don Vandervort writes or edits every article at HomeTips. Don has: